Roofs

Wood Framed Roofs

Wood-framed roofs fall into the same category as wood-framed walls. They simply disintegrate in a major tornado or hurricane. Next time you see TV news films of a tornado hitting a house, observe what goes first. Watch the roof!

Even when fastened to the tops of concrete walls, wood-frame roof and truss systems have not survived the high-category tornadoes and hurricanes.

Insulated Reinforced Concrete Roof Decks

The only known roof systems that have consistently survived high-category hurricane and tornado velocity winds have been built with structural reinforced concrete decks — securely and sufficiently connected to structural reinforced concrete or reinforced concrete block walls.

Because of their weight, concrete roofs typically must be supported by concrete walls.

Walls must be reinforced in order to resist the horizontal components of the wind as well as vertical wind forces from the wind as it affects the roof loads. Such walls are termed "bearing/shear walls." The wind forces imposed on the walls act perpendicularly to the face (plane) of the walls. They, in turn, translate into significant horizontal loads to the perpendicular cross walls supporting them.

In order to assure that the concrete shell structure will develop its full capability to resist the imposed destructive forces, it is essential that the roof structure provide a competent structural diaphragm incorporating a cast-in-place reinforced concrete slab or well-connected precast concrete planks in order to develop the full potential of a concrete shell.

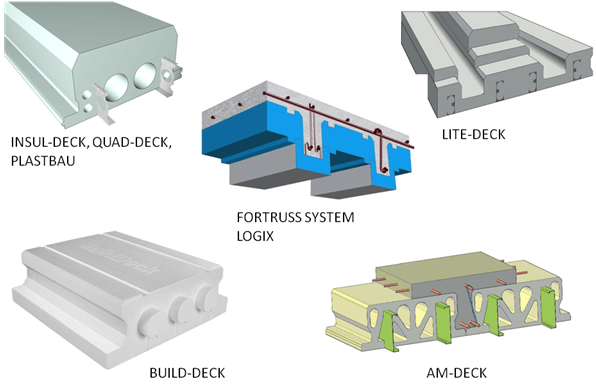

There are several manufacturers of insulating concrete forms in North America that can be used to support monolithically poured cast-in-place concrete slab systems. Several of these are shown below:

Figure 5. Typical insulating roof deck form planks manufactured in North America and designed for cast-in-place reinforced concrete roof decks.

Figure 6. Cross-section of a typical cast-in-place reinforced concrete roof deck formed with one of the typical ICF planks shown in figure above. The sheet metal channels embedded in the EPS adjacent to the concrete beam stems are the screw strips for subsequently affixing the drywall.

Ridge And Valley Beams

There can be a number of different approaches to the configuration of ridge and valley beams that might be used and will likely be developed by individual contractors. Figure 7 suggests several possibilities that have been shown to be workable.

Figure 7. Views show suggested layout of insulating forms for cast-in-place reinforced concrete ridge and valley beams integral with the reinforced concrete diaphragm roof deck.

Figure 8. Isometric cross-sectional illustration of the wall/roof shell, showing temporary formwork for the ridge beam and shoring still in place after pouring concrete for the roof deck diaphragm.

(Illustration courtesy of Quadlock Building Systems Ltd.)

Constructing the Concrete Roof Deck

Constructing a concrete slab for a structural roof is different from that for building a slab on the ground in that attention must concern two important objectives. One concern is that the concrete must develop the compressive strength intended by the structural engineer in the design of the roof deck. If the plan is not to install roofing material, (see reasoning below), the second important concern is to assure that the concrete remains impermeable to rainwater. Sufficiently waterproof concrete can be achieved, and is regularly used for water tanks, ships, pipe, and more. For an exposed-concrete roof installation, it is recommended that a competent concrete mix design consultant or concrete supplier be engaged to assist in the development of the concrete mix to be used.

Reinforced Concrete Roof

The intensity of a tornado is an act of nature that is not amenable to being controlled by human measures. Concurrently, the roof for a house is not a particularly large or costly element of the total cost of a house. So the recommended criteria for the minimum quality of the concrete to be used in an exposed-concrete roof deck should be on the side of higher strength. Inasmuch as the concrete roof will be exposed and not covered, it must necessarily be leak proof.

The little extra cost of employing a high quality concrete mixture for the roof slab is compensated for by elimination of the cost of roofing materials. Conventional roofing materials are stripped by high winds and become part of the flying missile stream, as well as being added to the clean up load.

When the roof is constructed as shown in details above, an additional offsetting roof assembly cost is achieved by eliminating attic spaces and their framing. Conventional ductwork may also be eliminated by use of heat pump mini-split HVAC systems. It has been estimated that air leakage of conventional duct systems may account for as high as 40% of wasted residential energy. Elimination of this source of energy waste can be accrued over the life cycle of a structure to an appreciable amount of energy cost savings. Energy savings alone, along with reduced insurance costs, can more than pay for an insulated concrete roof deck.

The savings in eliminating conventional roofing materials will also offset the cost of the concrete roof solution.

Roofing materials have not been used on concrete roofs on houses constructed on the island of Guam over their 50-year history. Leaks are rare, generally caused by faulty construction practices, and are easily repaired.

Air entrainment ("A/E") is normally thought of as making concrete resistant to freeze-thaw damage. Consequently it is not considered in environments that do not experience freezing.

However, A/E contributes important qualities to the character of a concrete mixture during placing and finishing operations — regardless of environment. Properly air entrained concrete is "lubricated' by millions of tiny air bubbles acting like ball bearings, enabling it to flow more freely.

What Can Be Done If the Roof Leaks?

As noted elsewhere in this site, on the island of Guam where they have built thousands of concrete roof decks over the years without supplemental roofing materials, roof leaks are rare. Annual rainfall is 100 inches.

Usually leaks result from a mistake that was made during the original construction. Usually they have been localized to a small area on the roof. One solution has been to seal the roof with one of the crystalline sealers that is available on the market. Xypex is a typical example. The manufacturer of the sealant should provide guidance.

Roof Appearance

The more innovative roof contractor may be interested in applying a texture to the roof, similar to those now commonly used on sidewalks and drives. There are a variety of concrete stamps, and stamping techniques available. Colored pigments in the concrete may also be considered as well as architectural textures like exposed aggregates. In sunny tropical regions, reflective colors and surfaces should be considered for the purpose of energy conservation. Similarly, in cold climates, the roof concrete may use dark colored pigments to help absorb some of the sun's radiation.